The Top Supply Chain Challenges: Shippers and Carriers Respond

The supply chain challenges you’re facing today likely look very little like those you envisioned at the beginning of 2020.

The COVID-19 pandemic caused chaos across every local, national and global supply chain, from product shortages to facility closures and beyond.

Yet somehow, shippers and carriers around the world have persevered, and they continue to ship and deliver goods every day.

What are the biggest challenges in today’s supply chain?

We asked 850 decision-makers to find out.

We took this opportunity to ask more than 850 of them about their biggest pain points in a supply chain automation research study.

Here’s what they said.

The Top Supply Chain Challenges for Shippers

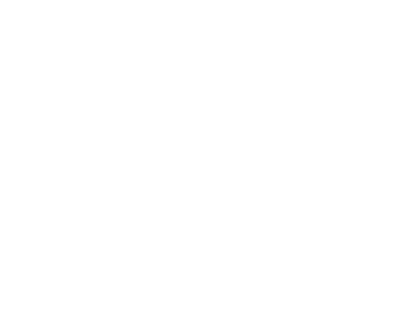

When we asked businesses to tell us their biggest shipping problems today, their top five responses were a mix of factors exacerbated by the pandemic and longstanding shipping concerns.

Shippers’ Top 5 Supply Chain Challenges:

- Keeping transportation costs down

- Keeping up with customer/industry demands

- Sourcing consistent, reliable carrier capacity

- Keeping up with the latest technology solutions and demands

- On-time pickup and delivery performance

3 Key Takeaways

1. It’s All About the Money

Controlling freight costs is an age-old issue in the transportation industry, and it has been an even bigger worry for shippers in recent years.

Even before the pandemic, shippers had been facing rising rates due to our place in the truckload market rate cycle — the COVID-19 volatility made it even tougher.

Most shippers were struggling with their own profitability issues, whether sales stopped or boomed, and the freight rates were not helping.

Another major factor, the supply of truck drivers, plummeted during the pandemic as drivers were unable or unwilling to work.

2. Fast & Free Shipping Is Pressuring Everybody in the Supply Chain

Customer demands for faster, cheaper service — the so-called “Amazon effect,” after the expectations created and heightened by the e-tail giant’s growing dominance — have intensified cost issues and strained an already thin carrier supply.

The two-day-free-shipping that has become the standard in ecommerce has set expectations for everyone, even in business-to-business transactions.

3. Keeping Up in the Technology Arms Race

Shippers’ concerns with keeping up with the latest technology solutions and demands can be seen as an outgrowth of regular competitive pressures.

When a new tool is introduced to the market for analytics, forecasting or any other aspects of logistics, it’s natural to worry that your competition is investing in it.

Are your competitors already benefitting from new tech and preparing to leave you behind?

Following a year when every company worldwide had to “go digital” in ways they couldn’t have anticipated, this technological arms race feels even more pronounced.

The Trouble with Technology: Digital-Specific Shipper Challenges

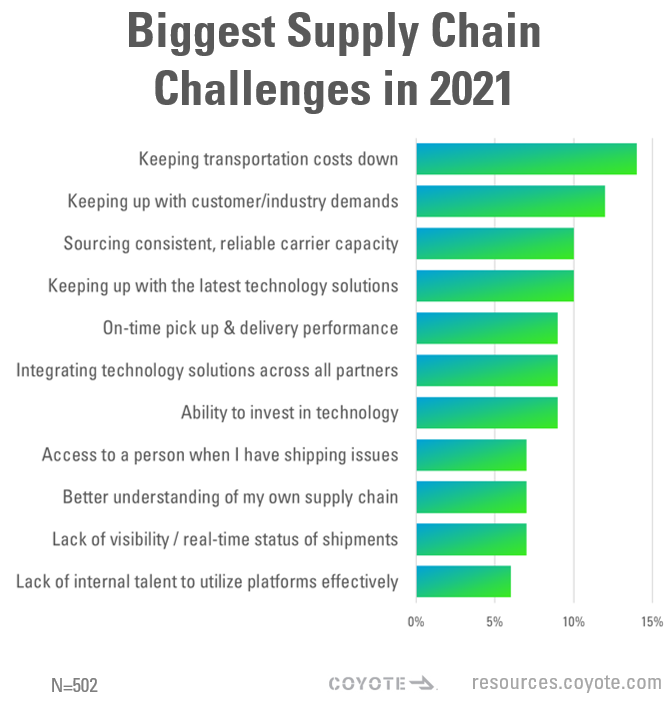

Because of the digital transformations companies underwent in the last year, we dove deeper into their specifically technology-related issues in supply chain.

When we asked them to rank their challenges regarding supply chain technology platforms and transportation management tools, their responses painted a picture of companies empowered by new tools but worried that they aren’t getting the most out of them.

What to Do with All That Data?

The #1 tech challenge shippers cited was analyzing the data their tools and platforms generate and deriving meaningful insights from that data. The current pace of technological change is daunting for many companies to handle.

Shippers of all sizes are impacted equally by this challenge: this was either the #1 or #2 ranked challenge for the smallest businesses we surveyed (with annual revenue below $200 million), our largest enterprise-scale respondents (annual revenue above $800 million) and everyone in between.

Your System Needs to Talk to My System

The #2 overall technological challenge shippers face is the related issue of integrating new tools with their existing platforms and the technical lift involved in this implementation.

There was some variance by business size in this response, however.

Small shippers tended to rate this a lower concern than larger ones, potentially because growing businesses are typically just starting to design their internal systems rather than introducing new tools into existing setups.

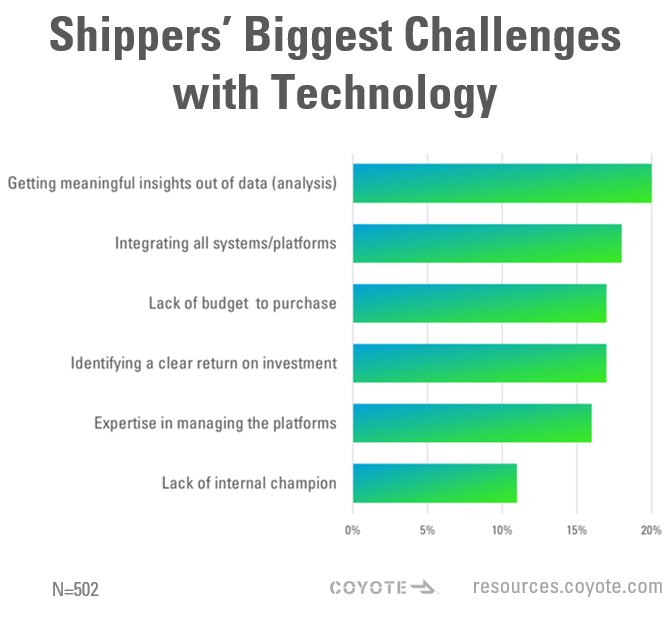

Overcoming Big Data Challenges

As more and more data has become available in recent years, companies have come to understand what kinds of data is more valuable than others to their supply chain strategy.

We asked shippers what data they are struggling to find that they think would help their organization mature. The dominant response, with 53% of the vote, was better operational data.

Operational data can cover many things — on-time pickup and delivery performance for specific carriers, facility ratings, shipment tracking and much more.

Generally speaking, it’s a window into the efficiency of a company’s supply chain and a crucial opportunity to see where you can make improvements.

Enterprise-scale shippers were the only segment of the study to choose better operational data less than half of the time (only 37%), with their preference shifting to better market or rate data.

Build a foundation: If you don’t have a TMS that efficiently collects and applies your operational data, you can’t go on to further market-driven strategies.

Does Size Matter? Breakdown of Shipping Challenges by Business Revenue

Business at different revenue levels experience different supply chain issues.

Let’s look at some key insights that highlight challenges at different points in business’ growth stages.

Small Shippers (<$200 Million): Cost-Conscious & Risk-Averse

Small businesses drove the #1 and #2 rankings of keeping transportation costs down and keeping up with customer/industry demands more than any other segment of our study.

Small shippers were 29% more likely than the overall group to rate keeping transportation costs down as their greatest logistics challenge, and 17% more likely to rate accelerating customer/industry demands as their biggest pain point.

It’s no surprise that they are the most concerned with keeping costs down — they typically do not move enough to secure contract rates.

This means that they are more exposed to the fluctuations of the spot market than their larger counterparts.

Cost also drove these businesses’ views on their technological challenges.

This was the only group to rate a lack of funding or budget to purchase tools as their #1 technological challenge.

Small shippers were 29% more likely to struggle with controlling costs and 17% more likely to struggle with rising customer demands.

Related: Get insights on how to invest your budget with the Small Business Guide to Logistics Technology.

Mid-Market Shippers ($200-$800 Million): Growing Pains

As we move up the scale, shipper challenges and priorities shifted away from strictly budgetary, toward the strategic.

While keeping transportation costs down is still their #1 challenge, only 12% of mid-market shippers thought so, compared to 18% of smaller businesses.

Votes were much more evenly spread out among mid-market shippers than among small ones, with five responses receiving 10% or more of their votes.

The increased willingness mid-sized shippers exhibit to invest in new technologies brings with it some predictable anxieties. They ranked data analysis for meaningful insights and integration of new platforms with existing systems as their top tech challenges.

Mid-market shippers are cost-consciousness (like smaller shippers), but also struggle to increase their technological capabilities and find consistent freight coverage (like larger shippers).

Enterprise Shippers (>$800 Million): Staying One Step Ahead

Even among this most well-capitalized set of businesses, keeping transportation costs down ranked as the #1 most common shipping and logistics challenge.

However, they were the only segment to have keeping up with the latest technology as their #2 biggest challenge.

When it comes to specific challenges with technology, they were the only segment to have identifying a clear return on investment as a top three concern.

For large shippers, optimization is the name of the game. They have already invested in tech infrastructure, but how do they get the most return out of that investment?

Carriers’ Top Supply Chain Challenges

Many of the same pressures the COVID-19 pandemic placed on shippers affected carriers over the past two years.

Carriers’ Top 5 Challenges:

- Keeping maintenance and operational costs down

- Keeping up with customer/industry demands (better, faster, cheaper)

- Unexpected time delay

- Keeping up with the latest government regulations

- Access to a person when I have transportation/logistics issues

The top two of these challenges are the very same ones that shippers rated at the top of their list.

They’re a powerful example of the way e-commerce pressures impacted all sides of supply chains last year.

Other trends we also saw in 2020 and into 2021 that strained carriers were:

- Maintenance costs rose.

Tools and parts were caught up in the same unstable supply chains that carriers themselves work in.

- Unplanned delays became more common.

Facility closures and understaffing issues left trucks stranded more often than normal throughout the pandemic.

Consumers pressure retailers, retailers pressure their suppliers, these suppliers pressure their suppliers, and everyone pressures carriers.

You Know the Challenges, Now Dive Deeper Into Solutions

Now that you’ve read about the challenges other shippers and carriers are facing this year, you’re probably interested to learn what they’re doing about them.

Are they hiring new talent?

Investing in new software?

Outsourcing parts of their supply chain strategy?

The 850 of your peers we surveyed didn’t just tell us their concerns — they gave us an insider’s look at the way they’re handling them with a powerful blend of human expertise and technological solutions.

Download the full research study to get more insights into the state of supply chain automation and start planning how you’re going to address your unique logistics challenges.